Automating pharmaceutical protocol management for speed and safety

Table of contents

Try Workflow Automation free for 14 days

In the pharmaceutical industry, standard operating procedures, clinical trial plans, and regulatory submissions aren’t just routine tasks. They’re important parts that directly affect patient safety, regulatory compliance, and ultimately, your organization’s ability to bring life-changing treatments to market.

But here’s the challenge: Manually managing these complex processes (and their associated workflows and required documentation) can cause a host of issues, like major delays, compliance challenges, and costly errors — all of which can wreak havoc on your operations.

There’s a way to avoid those problems and let your team work better and faster: using workflow automation in pharmaceutical protocols.

Workflow automation changes how pharmaceutical companies manage their rules, documents, and approval processes. It also makes it easier to follow rules, improves communication, and reduces risk.

But how exactly is automation changing the pharmaceutical industry? In what ways are manual processes holding back your team and organization, and what can automating those workflows offer? And how can you start incorporating automation into your protocols and processes and reaping the rewards that go along with it?

The unique complexities of pharmaceutical protocol management

This section will quickly touch on why protocol management in the pharmaceutical industry is so complex to begin with.

There are a number of unique challenges that come with pharmaceutical protocol management.

- Diverse documentation processes — Pharma is a heavily regulated industry, and as such, pharmaceutical organizations deal with a lot of paperwork. Pharma companies not only have to manage a lot of documents, but they also have to manage many different types of documents with very different workflow requirements. For example, the document requirements for clinical trial protocols may be different from regulatory submissions or quality management documentation.

- Multi-stakeholder collaboration — Pharma document approval workflows often include multiple stakeholders, both internal (for example, different internal teams like R&D, quality control, manufacturing, and legal) and external (like academic institutions and/or regulatory authorities, like the FDA). The more people/teams/organizations involved in a workflow, the more complex, challenging, and time-consuming it becomes.

- Strict regulatory requirements, which lead to more complex workflows — Pharma is one of the most tightly regulated industries. The more rules there are, the more complicated and involved the workflows become. For example, pharma companies must abide by Good Documentation Practices(opens in a new tab) (GDP), which dictates how all documents within the organization must be prepared, reviewed, approved, issued, recorded, stored, and archived — with non-compliance causing serious consequences.

- Regulatory changes — Pharma is very controlled, and it can be changed at any time. When this happens, companies must change their procedures, processes, and SOPs to reflect the new changes. And adjusting to those changes, particularly if processes are managed manually, can present major challenges for teams.

- Inspection readiness — In addition, pharma companies are subject to regulatory inspections. And during those inspections, documentation must be easily retrievable, with a clear trail of all changes, approvals, and implementation, which requires a high level of organization and accessibility.

How manual processes hold pharmaceutical teams back

If you’re still using manual or partly automated processes for protocol management, they’re making your organization very hard to work with.

Clearly, pharmaceutical protocols, documentation, and regulatory compliance present some complex challenges. And those challenges are only exacerbated by manual process management.

Manual processes hold pharmaceutical teams back in a variety of ways, including:

- Delays — There’s no denying it: Manual processes are just more time-consuming than automated processes. For example, let’s say your organization is going through an approval process for a new drug. If your team is doing the process by hand, the approval paperwork would have to go from one approver to another. This takes too long and can cause problems — like if one of the main people forgets to review the approval, letting it sit on their desk for weeks, causing the approval process to take longer. And in the world of pharma — where even minor product delays can cause millions in lost revenue — those delays can cause major damage.

- Increased risk of human error and inconsistencies — The pharmaceutical industry is home to a lot of smart, meticulous people. But no matter how smart or meticulous they are, they’re human, and when humans are in charge of manually managing a process, there’s always an increased risk for error. And in an industry as high-stakes as pharma, those errors can present serious (and expensive!) problems. Manually managing processes also opens the door for employees to interpret and approach workflows in their own unique and possibly incorrect ways, which can lead to inconsistencies across the organization.

- Increased risk of inaccurate or incomplete information — In pharma, protocols and approvals are always changing. There are usually many versions of documents, SOPs, and other processes, and many people are involved in each version. Information is always changing. If information is being updated manually, it takes a lot of time and has a high chance of making mistakes. This can cause problems for everyone involved. Manual management can also increase the risk of incomplete documentation or missed steps because pharma documentation is so complex. This can cause problems when audits or reviews are done.

- Collaboration challenges — Again, there are often numerous people, teams, and external parties involved in pharma protocols, documentation, and approval processes. Manual management makes it impossible for all stakeholders to collaborate in real time, which creates delays and inefficiencies in the workflows.

How workflow automation can transform pharmaceutical protocol management

Workflow automation in pharmaceutical protocols (for example, automated pharma document approval workflows, automated SOP tracking, or pharmaceutical regulatory compliance automation) is revolutionizing the way organizations manage their protocols, empowering teams to do their best and most efficient work, and allowing pharma organizations to streamline operations and get their products to market faster.

But what exactly does that transformation look like?

The next section will take a look at the different ways workflow automation can transform pharmaceutical protocol management.

Accelerated review and approval cycles

Automated workflows offer features that can dramatically reduce review and approval cycles, including:

- Parallel review capabilities — Many pharmaceutical protocols need review and signoff from multiple stakeholders. With automation, those people who need the document can all look at different parts of it at the same time. This can help speed up the process. For example, while the regulatory affairs team reviews compliance aspects of a protocol, the clinical operations representative can be assessing the implementation plan simultaneously.

- Automated routing and notifications — Automated systems also fix problems by automatically sending documents to the right people at the right time. They also send notifications to speed up the process between steps. For example, if a person involved hasn’t answered comments within the time limit — thus causing the process to slow down — the system can send a reminder to keep things moving forward.

- Real-time collaboration tools — Automated platforms let teams edit and comment in real time. This helps teams work better together in real time, which reduces the problems of less effective communication and collaboration — like email exchanges and document merges.

- Electronic signature integration — Pharmaceutical workflow automation platforms also have fully compatible electronic signature features. This means that people who are authorized can sign off on documents from anywhere, anytime, saving significant time and energy vs. chasing down physical signatures.

Enhanced compliance and reduced risk

Workflow automation also supports compliance and reduces risk in pharmaceutical protocol management via:

- Standardized processes — Automated platforms make sure rules and documentation follow your set rules every time. This makes it easier for everyone in the company to approve pharma documents. For example, automation ensures clinical trial document workflows are consistent across teams, so that no employees misinterpret the process or miss the necessary steps or required documentation.

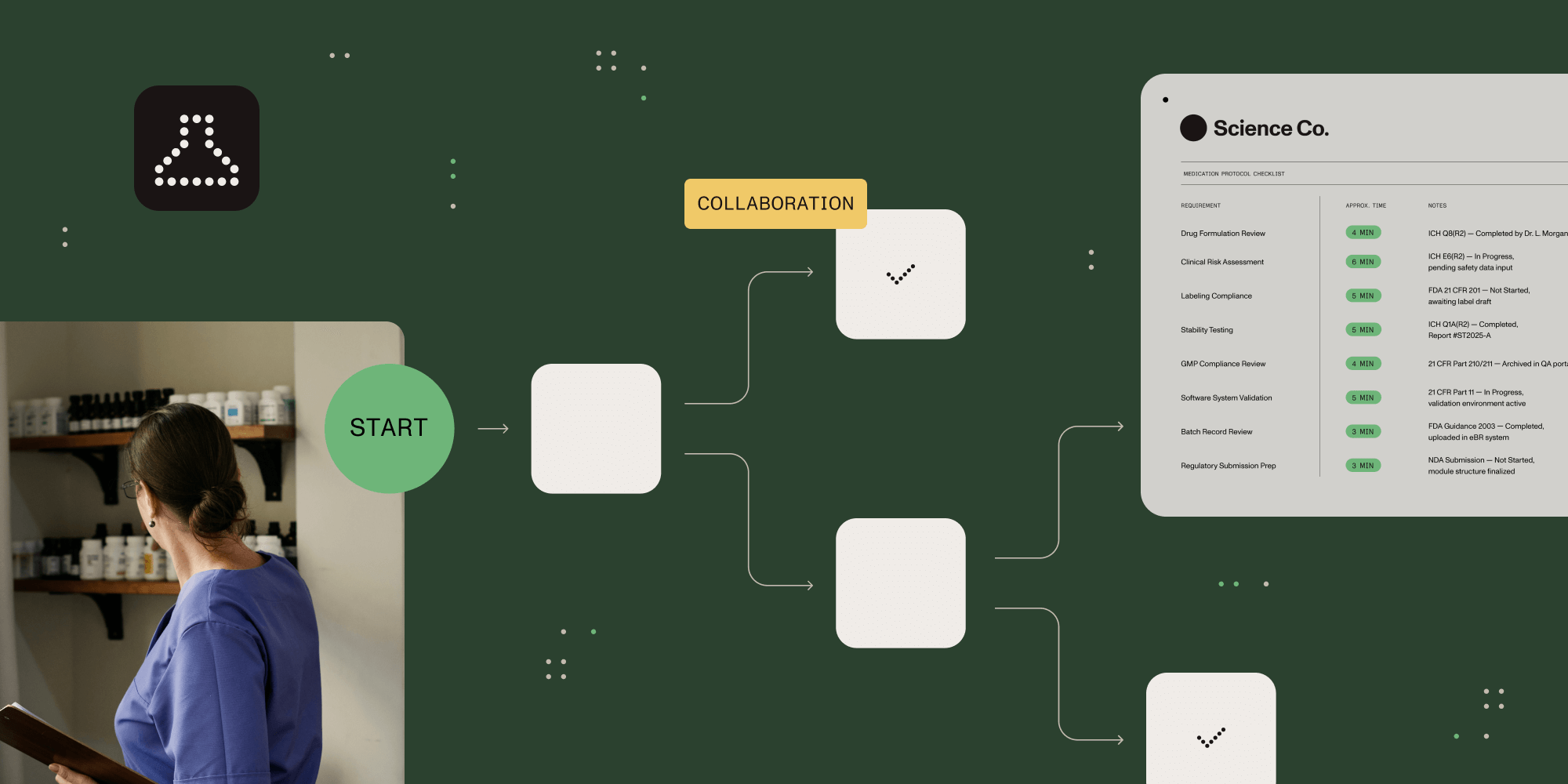

- Comprehensive audit trails — Every action in the system — from document creation to reviews, approvals, and access — is automatically logged with user information, timestamps, and version details. This creates an inspection-ready record of the complete document lifecycle — which is invaluable if and when your organization is audited.

- Validated electronic records — Workflow automation platforms also have 21 CFR Part 11-compliant features for electronic records and signatures. This means your electronic documentation will meet the rules.

- Automated training management — Part of compliance in pharmaceuticals is ensuring your team is up to date on all required training. Automated systems can track which people have read and agreed to updated SOPs. They can automatically start training when documents change, while keeping compliance records to show they have done it.

Improved document quality and consistency

Automation can also improve document quality and consistency across the organization in a variety of ways, including:

- Controlled templates and components — Automated systems provide approved templates and reusable content components, which ensure consistent formatting, tone, structure, and terminology across all your documentation.

- Automated versioning and control — Automated platforms can help keep versions of each document better. They can automatically label drafts, documents in process, and version history in real time. This ensures everyone on your team is working with the most accurate and up-to-date version of each document.

- Intelligent cross-referencing — With so many documents attached to each protocol, manually cross-referencing can be tough. Automated systems can better link many documents together, find possible problems or inconsistencies as related documents are updated, and send reminders to teams that need to update them.

- Automated quality checks — Many automated platforms also have built-in checks for common problems like missing parts, missing references, or different words. These checks can help teams find problems before documents are reviewed.

Integration with document repositories and systems

Another benefit of workflow automation in pharmaceutical protocols is the fact that many automation platforms integrate with existing infrastructure within the pharmaceutical industry, like:

- Veeva Vault — Many pharmaceutical workflow solutions work well with Veeva Vault, the standard content management platform. They create automated workflows to move documents through the right steps while keeping them safe.

- SharePoint — For pharma organizations using Microsoft SharePoint for document management, workflow automation can improve SharePoint’s capabilities with pharmaceutical-specific processes and compliance features.

- Electronic Common Technical Document (eCTD) Preparation — Pharma-friendly automated systems can facilitate the preparation of regulatory submissions in eCTD format(opens in a new tab), automatically structuring applications, reports, amendments, and other documentation for regulatory submission.

- Electronic Quality Management System (eQMS) coordination — Workflow automation can also integrate with existing eQMS platforms to ensure quality management-related events trigger appropriate document reviews and updates to affected SOPs or protocols.

Best practices for implementing pharmaceutical workflow automation

Looking to implement workflow automation for your pharmaceutical protocols and documentation? Here are a few best practices to keep in mind.

- Map your processes before automating — To successfully automate your processes, you need to know how they’re currently functioning. Map out the complete lifecycle of different document types, from creation through review, approval, implementation, and retirement. Map out the current process to find any problems or redundancies. Then, make automated workflows that fix those problems or redundancies and make the process more efficient.

- Start with high-impact documents — When it comes to automation, it’s important to start small. Don’t try to automate every document type at once, which can feel overwhelming. Instead, find out which protocol document workflows are currently causing the most pain in your organization. This could be clinical protocols with long review cycles or SOPs with frequent compliance issues. This will allow you to have an impact quickly, generate buy-in with your team, and set the stage for a more widespread automation implementation down the line.

- Choose pharma-specific solutions — When it comes to pharmaceutical requirements, not all automation platforms are created equal. Look for solutions made for life sciences. They should have features like 21 CFR Part 11 compliance, electronic signature validation, and support for industry standards like eCTD formatting. Pharmaceutical-specific solutions usually have built-in workflows that match regulatory requirements. This will make sure you and your team follow the rules and save a lot of time and energy during the setup process.

- Get your team involved — Your automation efforts will only be successful if they’re adopted by your team, which is why it’s important to get your team involved from the get-go. Include team members from all stakeholder groups — from medical writers to regulatory experts to scientists — when defining requirements, evaluating potential solutions, and defining workflows. When end users help shape the system, they’re much more likely to embrace it — and the more they embrace automation, the more successful it’ll be across your organization.

- Plan for integration — In pharma, there are many systems used to manage protocols. This means you need to choose a workflow automation platform that works with those systems. Whether your team relies on Veeva Vault, SharePoint, an electronic quality management system, or regulatory information management tools, make sure to do your research and ensure your automation platform integrates with your existing tech stack. These integrations will prevent redundancies or duplicate work, ensure consistency across systems, and create a more seamless experience for users.

Interested in automating your pharmaceutical workflows?

If you’re interested in learning more, you can schedule a 30-minute live, guided demonstration(opens in a new tab) or try Workflow Automation free for 14 days.