Material requisition software: Automate approvals and reduce errors

Table of contents

Material requisition is a formal process for requesting items before purchase. Automating this workflow reduces errors, speeds up approvals, and keeps production on schedule.

What is material requisition?

Requisitioned materials are items that go through a formal request and approval process before being purchased or released from inventory. This process ensures proper authorization, budget allocation, and tracking for manufacturing and operations.

Material requisition is how companies manage purchasing for manufacturing. It includes forms, routing, tracking, and approvals to ensure materials are bought correctly and within budget.

Done well, material requisition clarifies what’s needed and why. It also keeps inventory counts accurate.

The process authorizes purchases and records what was bought, from whom, and at what price.

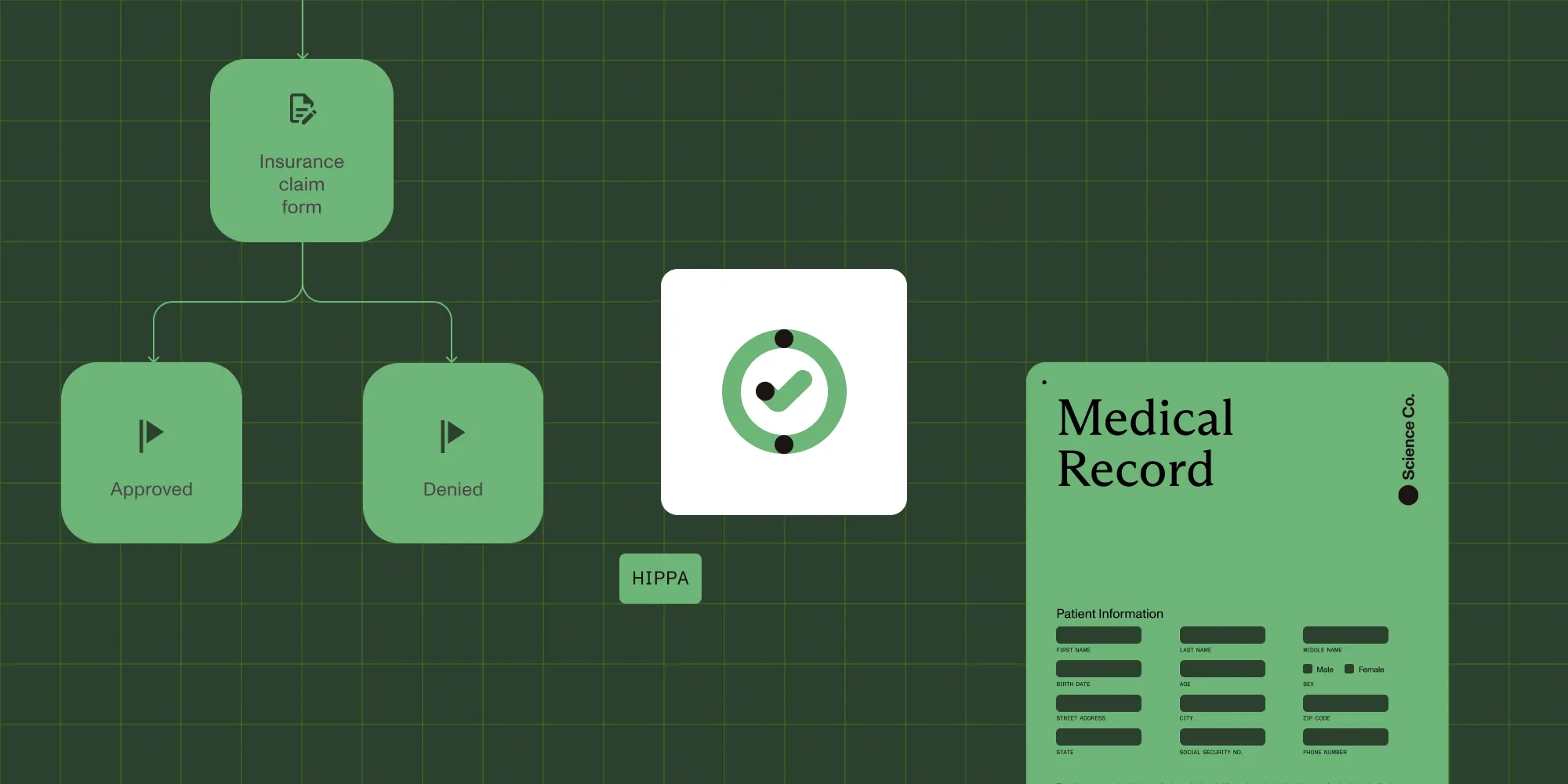

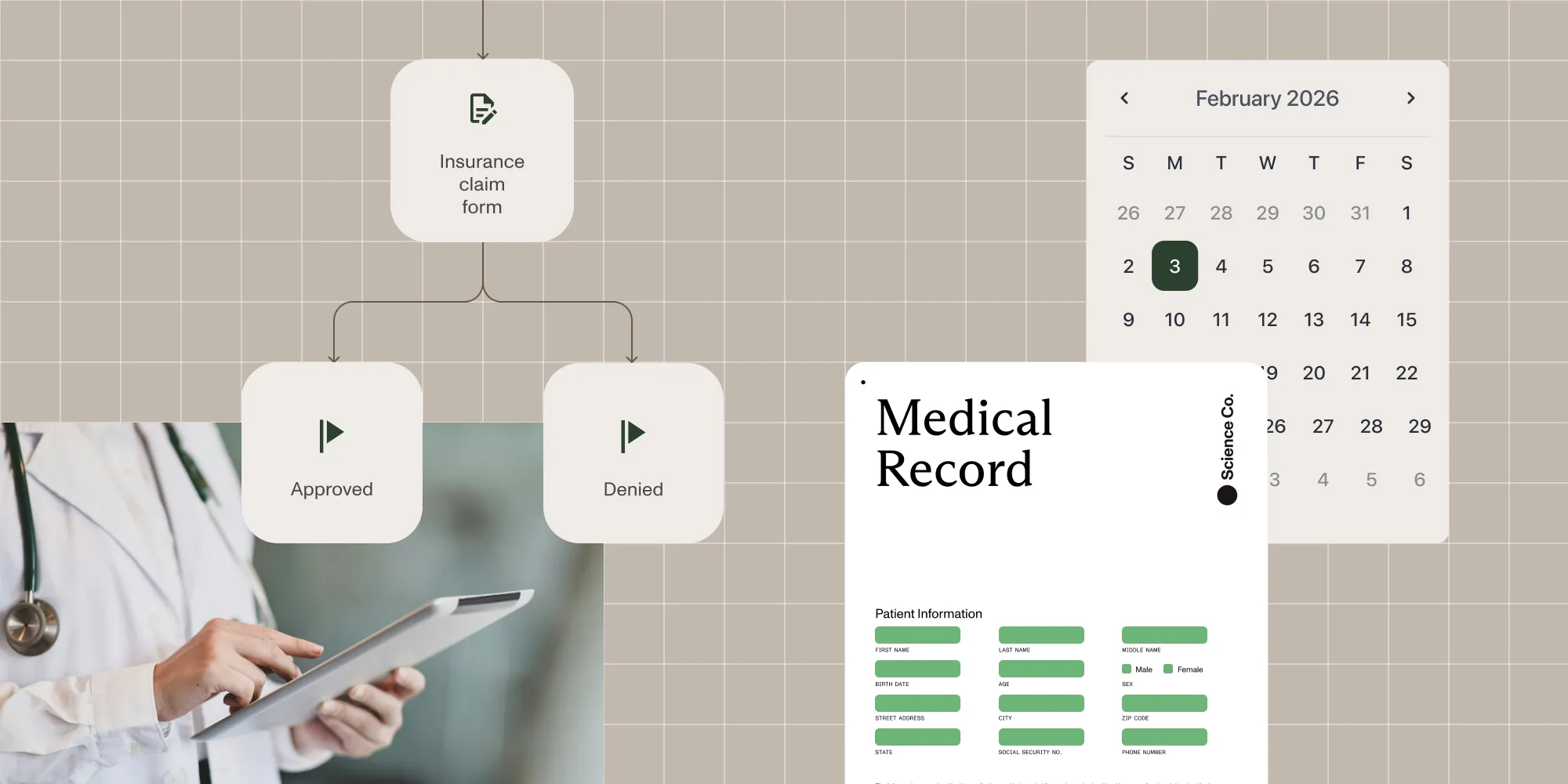

The material requisition process

A requisition form is central to this process. The form captures standard information about the request:

- Request date

- Department making the request

- Employee completing the form

- Item description (quantity, material, quality, unit of measurement)

- Purpose and intended use

- Desired delivery date

- Cost estimate (if known)

- Approval signature from supervisor or manager

Once completed, the production department routes the form to purchasing. Approvers review the request and may ask followup questions. They verify available funds and allocate budget to approved requests.

This approval step confirms that requested materials are affordable, available, and necessary. It prevents unnecessary or unauthorized spending.

The requisition process aligns purchases with budgets, priorities, and customer orders.

Example: Requisitioned materials in manufacturing

The following example outlines how material requisition works in practice. In this example, a boomerang manufacturer receives a large order from an Australian boomerang festival.

- The production department needs special woods, glues, and finishes to complete the order on time. They slot the job into the production schedule and assign staff.

- The supervisor submits a request for $10,000 in wood, $5,000 in finishes, and $1,000 in specialty glue. The form explains the festival order, notes the customer’s potential for repeat business, and includes a deadline for inspection and overseas shipping.

- The purchasing department reviews the request and assigns a job number. They enter the order into financial and accounting systems.

- Costs are drawn from a budget account for new business.

- A purchase order is issued. The production department can now submit the order and plan for delivery.

Example: Requisitioned materials in construction

Construction projects depend on having the right materials at the right time. Key considerations:

- Formal request process — Document material descriptions, quantities, and delivery timelines.

- Verify availability — Confirm materials are in stock before placing orders.

- Quality control — Ensure materials meet project specifications.

- Supplier collaboration — Build strong vendor relationships for reliable deliveries.

- Streamlined operations — A documented process keeps projects on schedule and within budget.

Problems with manual material requisition tracking

Many companies still rely on manual material requisition. These processes slow production and create other problems:

- Errors — Employees reenter data from paper forms into approval systems. Mistakes cause delays and downstream problems when wrong quantities are ordered.

- Delays — Production stalls when paperwork backs up or gets misrouted.

- Wasted staff time — Manual data entry consumes hours that could go to higher-value work.

- Inaccurate reporting — Manual processes undermine confidence in requisition data and the reports built from it.

These challenges point to a clear solution: automation.

Automating material requisition workflows

Automation tools change how material requisition operates. Online forms and automatic routing replace paper. Form data populates accounting ledgers and budgets without reentry. Staff spend time on higher-value work.

Automated processes cut errors and reduce paper storage needs.

Automation also improves employee satisfaction and vendor relationships.

Manufacturers who automate see better business outcomes.

Best practices for optimizing material requisition

- Establish clear policies — Define roles and responsibilities for each department involved in the requisition process.

- Standardize forms — Include material description, quantity, and cost on every request.

- Automate the process — Use software to reduce manual data entry and speed up approvals.

- Centralize tracking — Use a single system to manage all requisitions and reduce lost paperwork.

- Two-step approvals — Add oversight to catch issues before they become problems.

- Real-time tracking — Monitor requisition status and respond quickly to delays.

- Train staff — Ensure everyone understands the process and system.

- Analyze data — Identify trends in material usage to reduce waste.

- Monitor and evaluate — Review the system regularly and adjust as needed.

Get started with Nutrient Workflow

Nutrient Workflow automates requisitioned materials tracking with drag-and-drop process design, automatic routing, and real-time visibility. Start a free trial or request a demo.

FAQ

Requisitioned materials are items formally requested through an approval workflow before purchase or release from inventory. The process ensures proper authorization and budget tracking.

Nutrient Workflow automates the entire process — from request submission to approval routing to purchase order creation — with no coding required.

Typical fields include request date, department, item description, quantity, unit of measurement, cost estimate, purpose, delivery date, and approval signatures.

Yes. Nutrient Workflow connects with ERP systems, accounting software, and inventory management tools through APIs and prebuilt connectors.

Most customers are up and running within a few weeks with hands-on support from the Nutrient Workflow Customer Success team.