Supercharge Warp with Nutrient DWS MCP Server: From datasheet PDFs to production code

Table of contents

Nutrient DWS MCP Server integrates document processing directly into Warp’s agentic development environment. Process PDF datasheets with natural language commands, and generate run-ready code — all without leaving your terminal.

As a Warp(opens in a new tab) developer, you’ve experienced the power of agentic development — natural language prompts generating ready-to-run code in seconds. But what happens when the information your AI agent needs is locked inside documents like datasheets?

I know this situation all too well from my days as an embedded engineer, where critical information like register maps, timing diagrams, and calibration formulas are scattered across 50-page PDF datasheets. Even with Warp’s advanced AI capabilities, you can’t simply paste a malformed register table and expect clean, structured data that agents can work with.

I used to spend countless hours on “datasheet archaeology” — manually transcribing register values, cross-referencing timing requirements, and translating PDF specifications into code. This breaks the flow of agentic development and forces you back into manual, error-prone human workflows.

The solution? Nutrient DWS MCP Server integration with Warp.

Integrate Nutrient DWS MCP Server into Warp and turn PDF datasheets into structured, AI-ready data — no more manual parsing.

The MCP solution: Warp + Nutrient DWS integration

Warp’s agentic development environment is incredibly powerful, but it needs reliable data to generate accurate code. PDF datasheets contain the information your agents need, but in a format they can’t reliably parse.

Nutrient DWS MCP Server(opens in a new tab) solves this by integrating document processing capabilities directly into Warp using Model Context Protocol (MCP)(opens in a new tab). Instead of switching contexts or manually extracting data, you can now:

- Process PDF datasheets through natural language commands, or even ask your agent to do so.

- Access structured register maps, timing diagrams, and specifications.

- Feed this data directly to Warp’s AI agents for code generation.

- Maintain your agentic development flow without interruption.

This MCP integration transforms Warp into a complete datasheet-to-code pipeline.

Warp MCP integration in action: Raspberry PI example

This section will demonstrate how Nutrient DWS MCP Server transforms your Warp development workflow. I’ll build a Python program for Raspberry Pi that communicates with a BME280 humidity sensor(opens in a new tab) — a perfect example, because all the critical implementation details are locked in a PDF datasheet.

This example showcases how MCP integration keeps you in Warp’s agentic flow while handling complex document processing behind the scenes.

The starting point: Structured but incomplete

Here’s what the initial script looks like, but with the crucial implementation missing:

#!/usr/bin/env python3"""BME280 Humidity Sensor Reader for Raspberry Pi

Hardware Setup:- Connect BME280 VCC to 3.3V- Connect BME280 GND to Ground- Connect BME280 SDA to GPIO 2 (I2C SDA)- Connect BME280 SCL to GPIO 3 (I2C SCL)"""

import timeimport sys

class BME280HumidityReader: """BME280 humidity sensor interface."""

def __init__(self, i2c_address=None): """Initialize BME280 sensor connection.""" self.i2c_address = i2c_address # TODO: Initialize I2C communication # TODO: Verify chip ID # TODO: Configure humidity measurement settings # TODO: Read calibration coefficients

def read_humidity(self) -> float: """Read humidity percentage from BME280.""" # TODO: Read raw humidity data from registers # TODO: Apply calibration coefficients # TODO: Convert to percentage return 45.0 # Placeholder

def is_sensor_ready(self) -> bool: """Check if sensor is ready for measurement.""" # TODO: Check status register # TODO: Verify measurement completion return True

def get_sensor_info(self) -> dict: """Get sensor identification and capabilities.""" # TODO: Read chip ID register # TODO: Return sensor specifications return { "chip_id": "Not implemented", "humidity_range": "0-100% RH", "humidity_accuracy": "±3% RH", "humidity_resolution": "0.008% RH" }It’s a perfectly structured program, but all the actual implementation details are missing. Those TODOs represent hours of datasheet work, like finding register addresses, understanding calibration formulas, and implementing I2C communication protocols.

The MCP workflow: Document processing in Warp

Before diving into the configuration details, it’s worth seeing how the MCP workflow fits into your development process. By connecting Warp directly to Nutrient DWS MCP Server, document processing becomes a seamless part of the agentic flow. No context switching, no copy-pasting from datasheets — just structured data ready for your AI agent to use.

Configuring Nutrient DWS MCP Server

I added Nutrient DWS MCP Server to my Warp configuration. This gave Warp’s AI agents direct access to document processing capabilities:

{ "mcpServers": { "nutrient-dws": { "command": "npx", "args": ["-y", "@nutrient-sdk/dws-mcp-server"], "env": { "NUTRIENT_DWS_API_KEY": "YOUR_API_KEY_HERE", "SANDBOX_PATH": "/your/project/directory" }, "start_on_launch": true } }}With this MCP server running, Warp could now use DWS to perform document processing tasks such as extraction, conversion, signing, and much more!

Single prompt for document processing and code generation

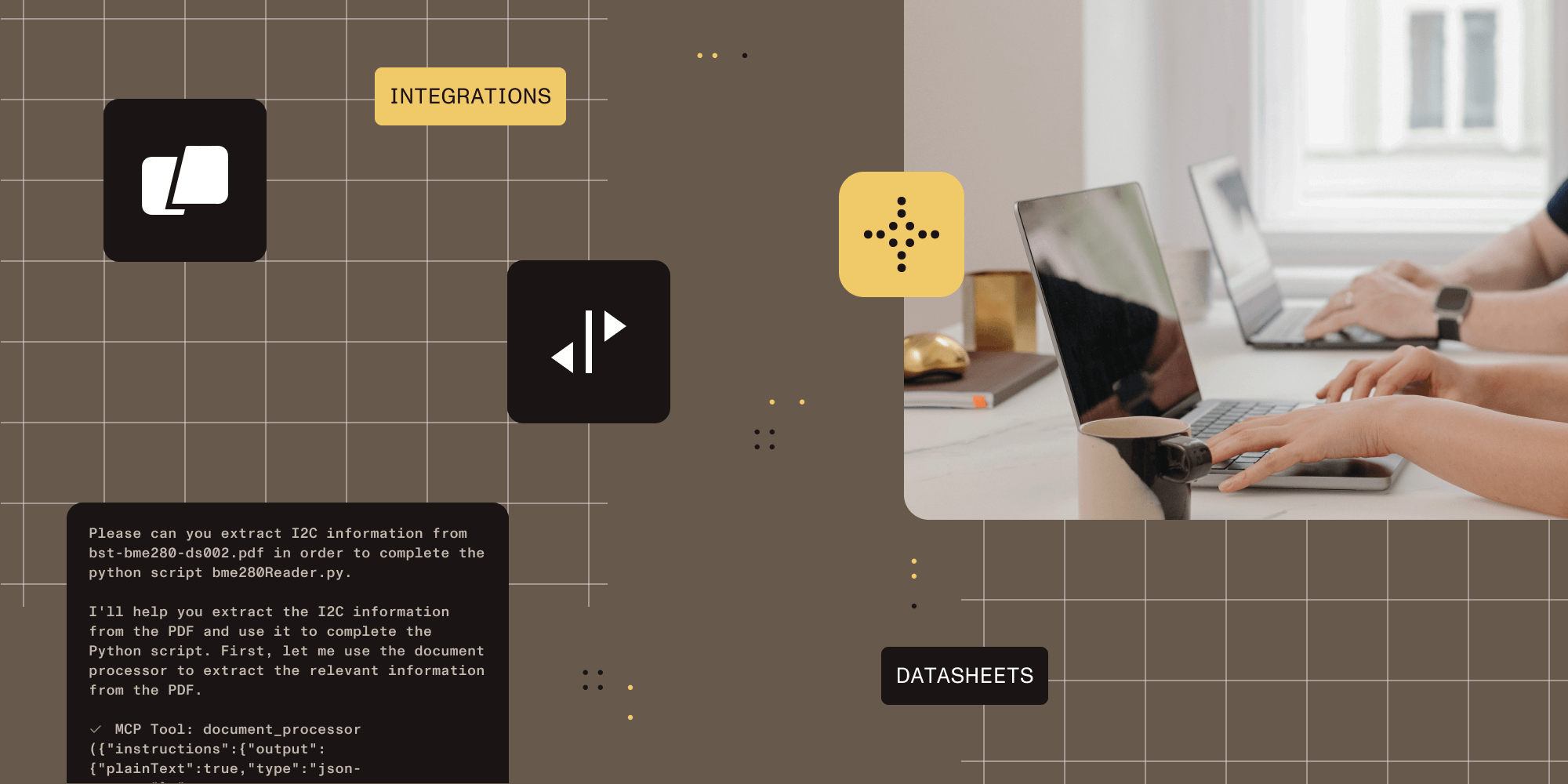

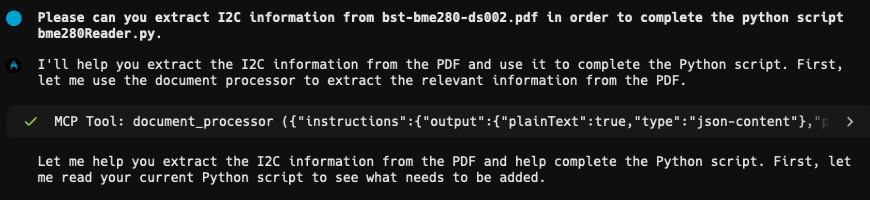

With the MCP server configured, I asked Warp to process the BME280 datasheet(opens in a new tab) and generate the complete Python implementation with a single natural language prompt:

Please can you extract I2C information from bst-bme280-ds002.pdf in order to complete the python script bme280Reader.py.Here’s where the magic comes in: Warp’s agent automatically calls Nutrient DWS MCP Server to extract the datasheet information. It then uses that structured data to complete your Python implementation — all from one prompt. The agent handles both document processing and code generation behind the scenes.

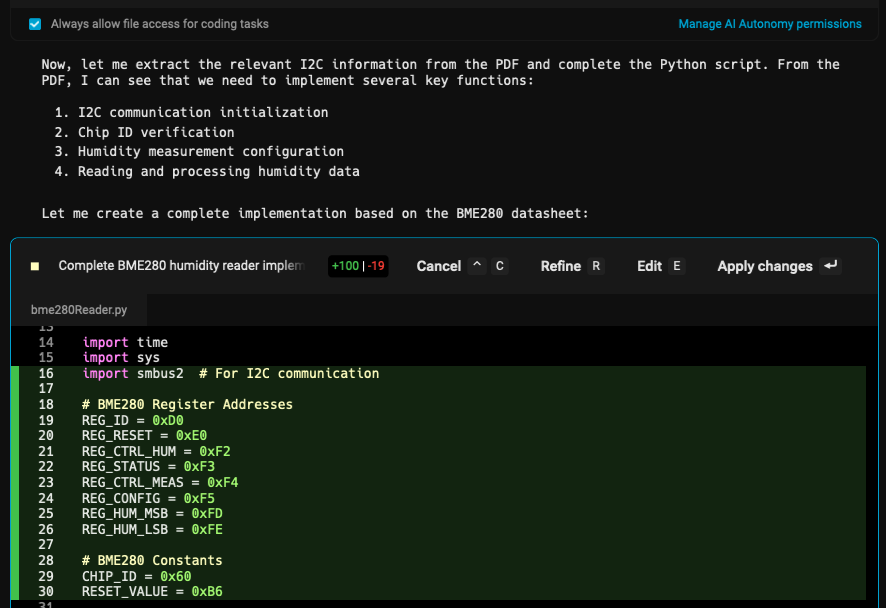

Warp’s AI agent had access to both my code structure and the precise BME280 specifications extracted by the MCP server. Here’s a truncated version of what it generated:

import smbus2 # For I2C communication

# BME280 Register Addresses (extracted from datasheet)REG_ID = 0xD0REG_RESET = 0xE0REG_CTRL_HUM = 0xF2REG_STATUS = 0xF3REG_CTRL_MEAS = 0xF4REG_CONFIG = 0xF5REG_HUM_MSB = 0xFDREG_HUM_LSB = 0xFE

# BME280 ConstantsCHIP_ID = 0x60RESET_VALUE = 0xB6

class BME280HumidityReader: def __init__(self, i2c_address=0x76): """Initialize BME280 sensor connection.""" self.i2c_address = i2c_address self.bus = smbus2.SMBus(1) # Use I2C bus 1

# Verify chip ID chip_id = self.bus.read_byte_data(self.i2c_address, REG_ID) if chip_id != CHIP_ID: raise RuntimeError(f'Unexpected chip ID: {chip_id:02x} (expected: {CHIP_ID:02x})')

# Reset the sensor self.bus.write_byte_data(self.i2c_address, REG_RESET, RESET_VALUE) time.sleep(0.1) # Wait for reset to complete

# Configure the sensor self.bus.write_byte_data(self.i2c_address, REG_CTRL_HUM, 0x01) # Humidity oversampling 1x self.bus.write_byte_data(self.i2c_address, REG_CTRL_MEAS, 0x27) # Normal mode, temp/pressure 1x self.bus.write_byte_data(self.i2c_address, REG_CONFIG, 0x00) # Filter off, standby 0.5ms

# Read calibration coefficients (from datasheet specification) self.dig_H1 = self.bus.read_byte_data(self.i2c_address, 0xA1) self.dig_H2 = self.get_signed_word_le(0xE1) self.dig_H3 = self.bus.read_byte_data(self.i2c_address, 0xE3) # ... additional calibration data reading

def read_humidity(self) -> float: """Read humidity using exact BME280 calibration formula.""" # Read raw humidity data msb = self.bus.read_byte_data(self.i2c_address, REG_HUM_MSB) lsb = self.bus.read_byte_data(self.i2c_address, REG_HUM_LSB) raw_humidity = (msb << 8) | lsb

# Apply the BME280's specific calibration algorithm # (Mathematical formulas extracted from datasheet) humidity = self._calculate_compensated_humidity(raw_humidity) return humidity / 1024.0

def is_sensor_ready(self) -> bool: """Check sensor status using datasheet-defined status bits.""" status = self.bus.read_byte_data(self.i2c_address, REG_STATUS) measuring = status & 0x08 # Bit 3 indicates measuring updating = status & 0x01 # Bit 0 indicates updating return not (measuring or updating)The results: Hours to minutes

What traditionally took 1–2 hours of PDF hunting, manual transcription, and careful implementation now takes about five minutes:

- 1 minute to set up the MCP server

- 2–3 minutes for the agent to call DWS to process the PDF and complete the implementation

- 1 minute to scan through the code and be amazed

The code isn’t just faster to create — it’s more accurate, with fewer human transcription errors, missed configuration steps, or misunderstood timing requirements.

Conclusion

Marrying technologies like Warp and Nutrient DWS MCP Server holds the ability to transform software development, even in areas where traditional agents haven’t yet been able to touch. By bringing document processing capabilities directly into Warp’s agentic development environment, it’s possible to

- Maintain agentic flow — Create feedback loops for the agent to follow, rather than requiring a human to feed the information.

- Eliminate manual transcription — Nutrient has years of experience reading/rendering/editing documents, and this integration leverages that expertise.

- Scale across complex projects — Apply the same workflow to any PDF-based technical documentation.

- Focus on innovation — Spend time building features instead of parsing datasheets.

Here at Nutrient, we’re seeing AI developer tools penetrate into more use cases, and by adding more integrations using MCP, it’s possible to give the agent more abilities to perform tasks autonomously — further reducing the time to code, and improving quality in the process.

What manual processes in your development workflow could benefit from AI automation through MCP integrations?

Get started with Nutrient DWS Processor API today and receive 200 free credits monthly! Perfect for watermark-free document processing targeting many use cases.