Simplify processes, ensure compliance, and boost efficiency with Nutrient’s automated workflow solutions designed for the food and beverage industry.

USE CASES

Support safe, consistent operations across supply, compliance, and innovation with workflows that scale from kitchen to enterprise.

Automate the documentation and tracking of safety inspections, certifications, and regulatory submissions.

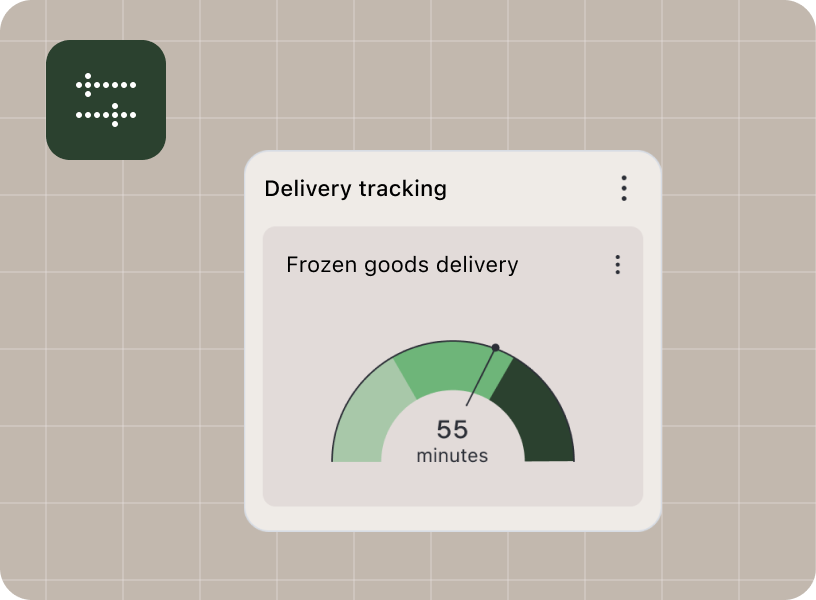

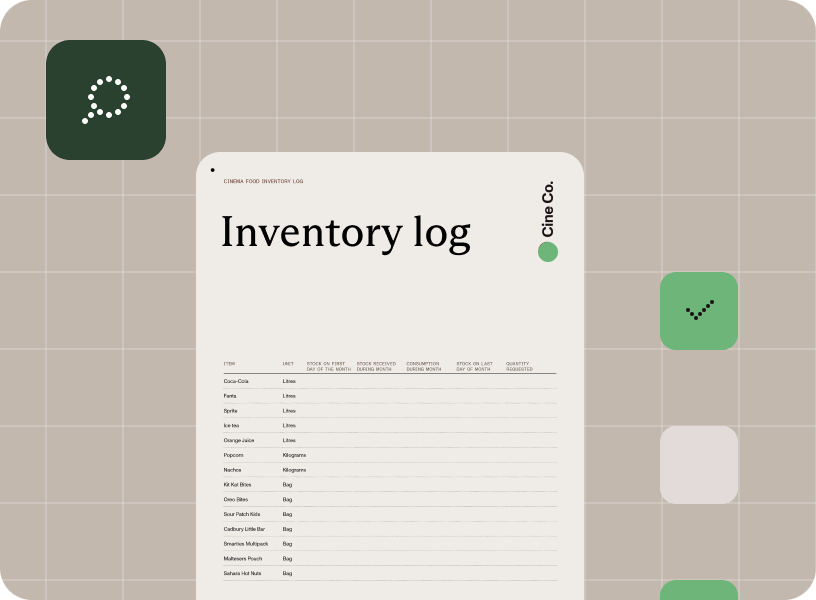

Optimize procurement, inventory tracking, and vendor approvals to keep the supply chain running smoothly.

Automate quality control processes to ensure consistent product standards and reduce waste.

Streamline the R&D process for new recipes and products — from initial concept to market launch.

Automate training and certification workflows to ensure all staff meet industry safety and quality standards.

Workflow Automation integrates with your tech stack — including finance systems, procurement platforms, and approval tools — using APIs, webhooks, or SFTP. No extra middleware required.

Contact us today to find out how workflow management can help food and beverage companies.

If it’s a process with steps, rules, or a spreadsheet, it can probably be automated. Common use cases include:

Nutrient offers a no-code platform where you can drag, drop, and deploy digital workflows — fast. Whether you’re running a commercial kitchen or a multisite manufacturing plant, you can digitize and automate your processes with conditional logic, notifications, form routing, and integrations.

Yes. Nutrient workflows can enforce checks, capture digital sign-offs, and maintain secure, time-stamped records. You’ll have an audit trail that shows you followed protocol — no lost paperwork, no guesswork.

Nutrient is mobile-friendly and built to handle real-world pressure. Whether you’re on the plant floor or walking the freezer aisle, you can access, complete, and route workflows from any device. No paper. No bottlenecks.

Absolutely. We take data security seriously. Nutrient includes robust access controls, encryption, and compliance features to make sure sensitive information stays in the right hands.